Halogen-free flame retardant specialized for modified PA66

-

Post Date:

Jun 01,2016

-

Expiry Date:

Nov 28,2016

-

Detailed Description:

Cas No. :225789-38-8

Specs:LFR-8006

LFR-8006

Halogen-free flame retardant specialized for modified PA66

1. Introduction:

LFR-8006 is one P&N synergistic flame retardant. It is white powder with low dust, high temperature resistance and non-migration. It is mainly applied to engineering plastics such as nylon 6 and PA66 (glass fiber reinforced and unreinforced) series and TPE (TPEE, TPU and PEBA).

2. Specification:

Item Unit Target value

P content %(w/w) 19-20%

Density g/cm3 1.25

Bulk density g/cm3 0.30-0.40

Moisture %(w/w) <0.25

Initial decomposition temperature ℃ >350

Average particle size(D50) μm 30-40

3. Application:

a. 8006 is especially suitable for nylon system (PA6, PA66 etc) with high glass fiber reinforced. The flame retardant nylon can achieve excellent mechanical and electrical properties.

b. In glass fiber reinforced PA6 or PA66, the additive amount of LFR-8006 is 15-20wt%, which could enable the material to reach UL94 V0 rating at 0.8mm-1.6mm thickness. Subject to the polymer grade, processing condition and glass fiber reinforcement, the additive amount of this flame retardant may vary.

c. 8006 has better thermal stability, wide processing window to various equipment, and the flame retardant performance is efficient and very stable.

d. 8006 can also be compounded with other efficient halogen-free flame retardant (synergist) to further improve comprehensive mechanical and electric properties, which help to satisfy the increasing stringent demands of terminal applications of plastic modification industry.

Suggestion of usage

In the processing, it is important to pre-dry the polyamide before mixing with LFR-8006. If possible, the resulting moisture content should be below 0.1% (by wt.). Pre-drying of LFR-8006 is not necessary. However, pre-drying (at 120℃ for 4 hours) is recommended, if very low moisture contents must be avoided.

The mixing and processing methods customary in powder processing of polymers can be used with LFR-8006. Prevention of dust fires and dust explosions or the relevant national regulations must be observed.

The optimum conditions for incorporating should be determined in each individual case. Care must be taken to ensure homogeneous dispersion of all components. The temperature of the polymer melt should not exceed 320℃.

4. Packaging & Storage:

20KG in one paper-plastic composite bag, which is lined with plastic bag

Sealed storage in dry, dust-proof and cool place

-

CAS Registry Number:

225789-38-8

-

Synonyms:

;Aluminum tris(diethylphosphinate);Aluminum diethylphosphinate;Diethylphosphinic acid aluminum salt;Diethyl Phosphinic Acid Aluminum;Ammonium polyphosphate(APP-0MF*);Ammonium polyphosphate(APP-0M);

-

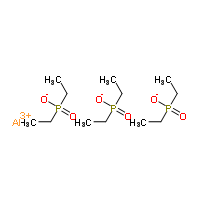

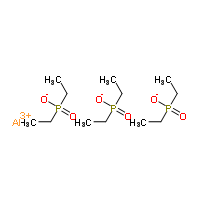

Molecular Formula:

C12H30AlO6P3

-

Molecular Weight:

390.2658

-

Molecular Structure:

-

Company:

Jiangsu Liside New Material Co., Ltd.

[ China ]

-

Contact:

Jason Huang

-

Tel:

+86-523-88660000

-

Fax:

+86-523-88663699

-

Email:

jason@liside.com

Inquiry